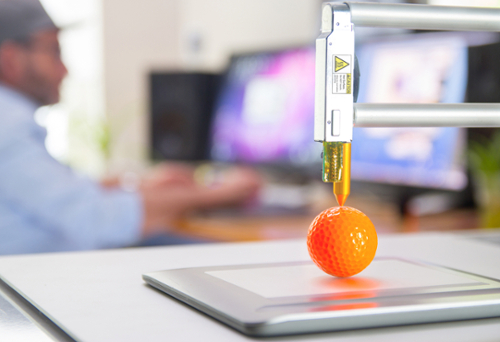

3D printing creates three-dimensional objects with computers. This additive manufacturing technology has experienced widespread growth in automotive, aerospace, electronics, medical, and other consumer markets. 3D printers stack layers of smaller pieces of materials to create objects weighing from a few ounces to a quarter ton. (See fused filament fabrication, vat polymerization, or powder bed fusion.) 3D printing also creates potential risks for workers exposed to heated filaments, polymers, or powders. While occupational exposure limits for these emissions haven’t been established, these tips can help reduce hazards and keep employees safe:

1 Limit access to the equipment.

Allow only trained and authorized personnel to use 3D printers. Be sure training includes information on all potential hazards and ways employees can protect themselves. Consider using training resources such as the Nanotechnology Research Center’s infographics on 3D Printing with Filaments or 3D Printing with Metal Powders.

2 Place printers in an isolated location.

Enclose printers and provide ventilation to capture chemical emissions. If an isolated enclosure is not possible, select a room or location that has good air distribution and exhaust to the outdoors.

3 Use materials with lower emissions when possible.

Choose material that meets engineering requirements and produces the least amount of ultra-fine particles (UFPs) and volatile organic compounds (VOCs). Refer to the U.S. Department of Human Services’ Health Hazard Evaluation Program publication for ways to determine hazards. Buy from a manufacturer who places a priority on emissions safety and whose equipment meets the American National Standards Institute (ANSI)/Underwriters’ Laboratories (UL) 2904 Compliance Standard.

4 Reduce time spent near 3D printers.

Limit time spent near a running 3D printer to prevent contact with harmful materials. For quality control purposes, consider setting up cameras to monitor the printer.

5 Wear personal protective equipment (PPE).

The employer needs to conduct a job safety analysis using the Hierarchy of Controls to determine the required PPE needed for workers. This may include the use of commercial respirators, splashproof eye protection, and flame, chemical, or particulate-resistant coveralls to block exposure to VOCs and UFPs. Also, wear neoprene or nitrile gloves when handling all uncured materials coming out of the printer.

For more information, visit the National Institute for Occupational Safety and Health’s Additive Manufacturing/3D Printing website.