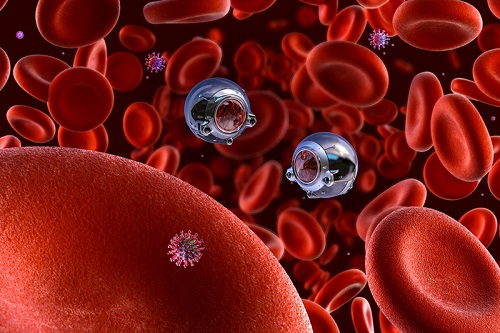

Big things are happening in the workforce with small materials called engineered nanomaterials (ENMs). These tiny, produced particles are between 1 and 100 nanometers in size. The width of a human hair is about 90,000 nanometers.

ENMs make existing products stretchier, stronger, brighter, better at conducting electricity, or more reactive. When ENMs are mixed into plastic, paint, or metal, they can give those materials these special properties, too. Makeup, sunscreen, food containers, appliances, clothes, coatings, computers, and sports equipment can all have ENMs. ENMs are also used in state-of-the-art sensors and medical technologies. You may be using products with ENMs without even knowing it!

Whether ENMs cause harm depends on many factors, including the type of ENMs and the route of exposure. ENMs may be aerosols, suspended in liquid, or bound in solid material. According to the National Institute of Occupational Safety and Health (NIOSH), studies on animals show that some ENMs may cause cancer, skin and eye irritation, or be toxic to organs. Also, since ENMs are often added to coatings or other chemicals, they can create complex “co-exposures.” Here are ways to reduce unintended exposure to ENMs:

1 Find out if there are ENMs in the workplace.

Conduct a thorough workplace assessment to identify possible sources of ENM exposure. One way is to use NIOSH’s Nanomaterial Exposure Assessment Technique (NEAT 2.0). NEAT 2.0 uses industrial hygiene methods to look at full-day exposures and filtering samples in the worker’s breathing zone.

2 Use NIOSH’s recommended exposure limits (REL) to determine the risks.

NIOSH provides RELs for the following nanomaterials: carbon nanotubes/nanofibers, nanoscale titanium dioxide, and silver nanomaterials. NIOSH’s Occupational Exposure Sampling for Engineered Nanomaterials explains nanomaterial sampling techniques.

3 Control exposure.

Once the assessment is complete, use the hierarchy of controls to reduce or eliminate the exposure. Address hazards by moving from the most to least effective method. Try to physically remove the risk, replace the hazard; isolate workers from the hazard; change the way employees work; and protect the workers with personal protective equipment (PPE).

4 Train and educate employees.

Train workers on the hazards of ENMs, safe handling practices, proper use of PPE, and emergency procedures.5 Monitor and survey the program.

Regularly monitor the workplace for ENM exposure levels and conduct medical surveys to detect any potential health effects in workers.

6 Comply with regulations.

Stay up-to-date with regulations and guidelines related to ENM exposure and related standards.

Employers need to make workers’ health and safety a priority when dealing with ENMs. A helpful and easy-to-use visual resource for the workplace is the NIOSH poster, Controlling Health Hazards When Working With Nanomaterials: Questions to Ask Before You Start.

We offer free in-person or virtual consultations to help employers comply with OSHA standards and regulations, and these consultations are free. Contact a Texas Occupational Safety and Health Consultation (OSHCON) professional at OSHCON@tdi.texas.gov or 800-252-7031, Option 2.