In 1950, the National Safety Council introduced the Hierarchy of Controls, a safety system aimed at reducing workplace hazards. This framework became part of government regulations when the Occupational Safety and Health Administration (OSHA) was formed in 1970. In the 1980s, OSHA’s educational branch, the National Institute for Occupational Safety and Health (NIOSH), emphasized the program. However, it was not until NIOSH’s 2007 national safety initiation, Prevention through Design, that the current five-step program to prevent or reduce occupational injuries, illnesses, and fatalities came into focus.

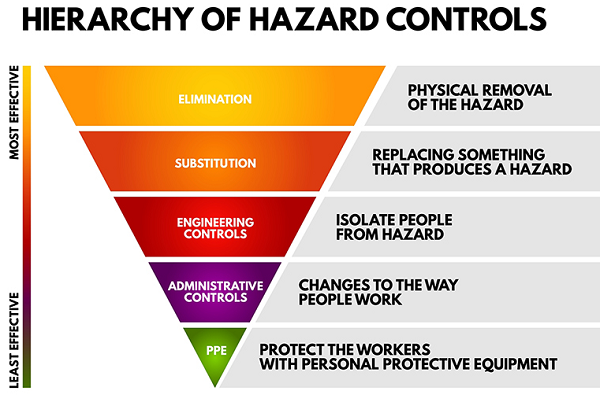

The Hierarchy of Controls features an inverted pyramid as a step-by-step approach to eliminate or reduce risks in the workplace. It ranks these controls from most to least effective:

1 Elimination.

Elimination removes the hazard at the source. This could include changing the work process to stop using a toxic chemical, heavy object, or sharp tool. It is the preferred solution to protect workers because no exposure can occur.

2 Substitution.

Substitution replaces the hazard with a safer alternative. Examples of substitution include using smaller quantities of hazardous material or simplifying complex instructions or tasks. Effective substitutes reduce harmful effects and do not create new risks.

3 Engineering controls.

These controls use physical changes to isolate people from the hazard. Examples of engineering controls include ventilation systems, guardrails, and machine guards. NIOSH's Engineering Control database is a valuable resource for finding specific control technology information.

4 Administrative controls.

This control method involves changing the way people work. Examples include rotating workers to limit their exposure, scheduling work at cooler times of the day, and restricting access to dangerous areas.

5 Personal protective equipment (PPE).

PPE is the last line of defense and involves providing workers with protective gear such as gloves, goggles, or masks. While PPE is crucial, it should not be the only control method. Employers should explore other control options before relying on PPE.

Following the Hierarchy of Controls leads to safer systems that reduce the risk of illness or injury. But, it's important to consider factors such as time, location, and the level of worker involvement when selecting control methods. Involving workers in the hazard control process and using a hazard control plan are essential.

For more information, download DWC’s free Job Hazard Analysis Fact Sheet, or stream job hazard analysis workplace safety videos. DWC’s safety training professionals can also help you reduce hazards at your workplace. For more information, visit www.txsafetyatwork.com or call 800-252-7031, option 2.